소닉카지노 & 2024년 이벤트 정보

소닉카지노 - 카지노사이트의 공식적인 대리점, 비타민을 여러분에게 소개합니다.

저희는 소닉카지노로부터 받은 2억 원의 보증금을 통해 서비스의 안정성을 유지하고 있습니다.

고객님의 만족과 안정을 위해, 어떠한 문제가 발생하더라도 보증금을 통해 전액 책임을 지고 환불 조치를 취해드립니다.

저희 바코드 전용 가입코드 이용 시 모든 문제를 원활하게 처리해드리겠습니다. 가입하실 때 가입코드 확인을 잊지 마세요.

바코드, 대한민국 최정상의 검증 업체가 보증하며, 모든 검증 절차를 완료한 소닉카지노를 여러분께 자신 있게 추천합니다.

가입코드 : 66

카지노사이트 소닉카지노 바로가기

소닉카지노도메인의 특징 소개

소닉카지노에는 다양한 슬롯 게임과 함께 인기 바카라 게임이 포함되어 있습니다.

사용자가 손쉽게 베팅할 수 있는 깔끔한 인터페이스와 함께, 전통 포커 카지노가 소닉카지노로 재탄생하였습니다.

기존 포커카지노 사용자들은 자신의 계정으로 소닉카지노에도 로그인 가능합니다.

토스뱅크에 가입하는 것 역시 소닉카지노에서 가능한 옵션입니다.

토스뱅크 가입에 대한 제한이 많은 다른 사이트와는 다르게, 소닉카지노에서는 가입을 허용해주고 있습니다.

가입코드 : 87

카지노사이트 소닉카지노 바로가기

소닉카지노사이트 혜택 안내

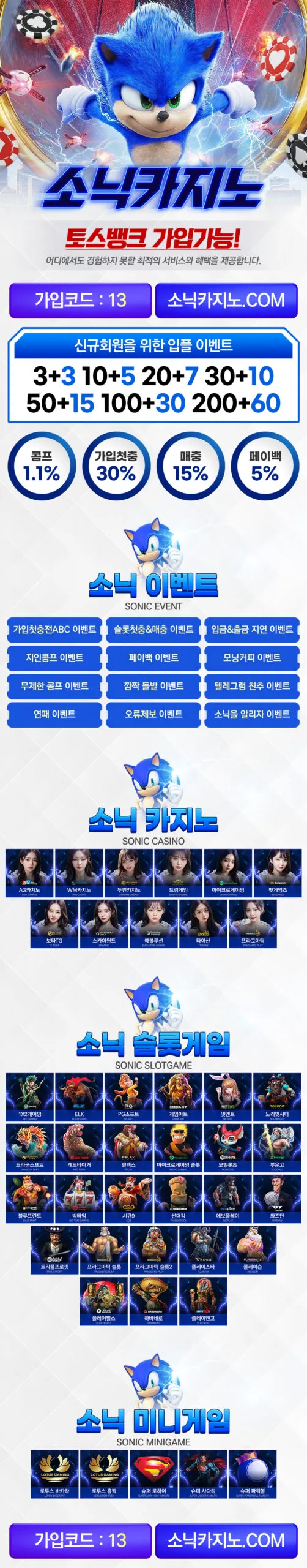

입금 플러스 – 3+3 10+5 20+7 30+10 50+15 100+30 200+60

가입첫충 : 30% 보너스

무한매충 : 15% 보너스

페이백 5%

콤프 : 1.1%

토스뱅크 가입 가능

가입코드 : 59

카지노사이트 소닉카지노 바로가기

소닉카지노-카지노사이트 이벤트

1. 모닝커피 이벤트

2. 슬롯첫충&매충 이벤트

3. 소닉을 알리자 이벤트

4. 페이백 이벤트

5. 입금&출금 지연 이벤트

6. 깜짝 돌발 이벤트

7. 가입첫충전ABC 이벤트

8. 텔레그램 친추 이벤트

9. 지인콤프 이벤트

10. 연패 이벤트

11. 무제한 콤프 이벤트

12. 오류제보 이벤트

가입코드 : 62

카지노사이트 소닉카지노 바로가기

소닉카지노 가입코드 혜택 정리

입금 플러스 – 3+3 10+5 20+7 30+10 50+15 100+30 200+60

가입첫충 : 30% 보너스

무한매충 : 15% 보너스

페이백 5%

콤프 : 1.1%

토스뱅크 가입 가능

가입코드 : 9

카지노사이트 소닉카지노 바로가기

소닉카지노 소개

국내 재정력 최고를 자랑하는 카지노 플랫폼

기존의 포커 카지노를 혁신하고 개선하는 과정

여러 인증 사이트에서의 검증을 통한 신뢰성

토스뱅크 가입 가능

다양한 혜택과 대규모로 진행되는 여러 이벤트를 제공합니다.

회원 대상 1.1% 리베이트 비율이 제공되며 혜택을 누립니다.

새로 가입하는 회원에게는 30% 추가 보너스가 제공됩니다.

충전 시, 15% 입금 보너스가 제공됩니다.

누적 충전액에 기반해 5% 페이백을 받을 수 있습니다.

입금 별도 보너스: 3+3, 10+5, 20+7, 30+10, 50+15, 100+30, 200+60

다양한 슬롯 머신과 카지노 게임을 제공합니다.

강력한 재정 인프라가 지원하는 신속한 입출금 처리를 경험하세요.

최고의 고객 서비스를 통해 회원님들에게 최상의 경험을 드립니다.

가입코드 : 47

카지노사이트 소닉카지노 바로가기

소닉카지노 사이트 다양한 게임종류 안내

1. 슈가 러쉬 X마스

2. 블루 프린트

3. 게이츠 오브 올림푸스

4. 머니 트레인4

5. 더 그레이트 피그비 메가페이

6. 레거시 오브 데드

7. 하이퍼노바 인피니티 릴스

8. 소닉미니게임

9. 플레이스타

10. 1X2게이밍

11. 에보플레이

12. 트리플 프로핏

13. 더 도그 하우스 메가웨이즈

14. 릴렉스

15. 더 도그 하우스 메가웨이즈

16. 문 프린세스 100

17. 마이크로게이밍

18. 와즈단

19. 로투스 바카라

20. 하이퍼노바 인피니티 릴스

21. 슈퍼 로하이

22. 마이크로게이밍

23. 더 도그 하우스 메가웨이즈

24. 슈가 러쉬

25. 마종 웨이즈 2

26. 마이크로게이밍 슬롯

27. 마종 웨이즈 2

28. 문 프린세스

29. 타이산

30. 산타스 스택

31. 더 트위티 하우스

32. 5 래빗스 메가웨이즈

33. 블랙 맘바

34. 썬더킥

35. 더 그레이트 피그비 메가페이

36. 드림게임

37. 슈퍼 로하이

38. 5 래빗스 메가웨이즈

39. 보타TG

40. 톰 오브 매드니스

41. 골드 킹

42. 슈퍼 사다리

43. 레거시 오브 데드

44. 플레이앤고

45. 프라그마틱

46. 레프리칸 리치스